The ITER device, currently under construction in the south of France, will study the potential of controlled nuclear fusion to provide energy for mankind. In order to study the behaviour of this device, a set of monitoring systems (referred to as Diagnostics) is required. These Diagnostics will provide the information required to understand the performance of the device.

GEMS Engineering is deeply involved in and fully devoted to the success of the ITER project. As a result, our main projects are in connection with ITER, and - more closely - to its diagnostic systems.

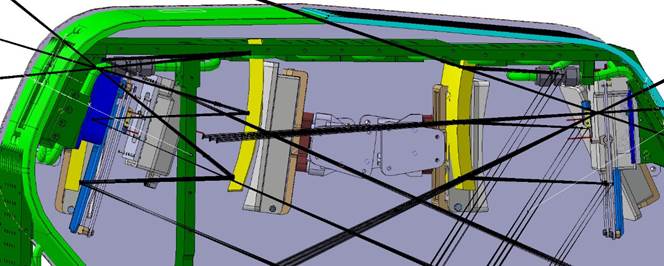

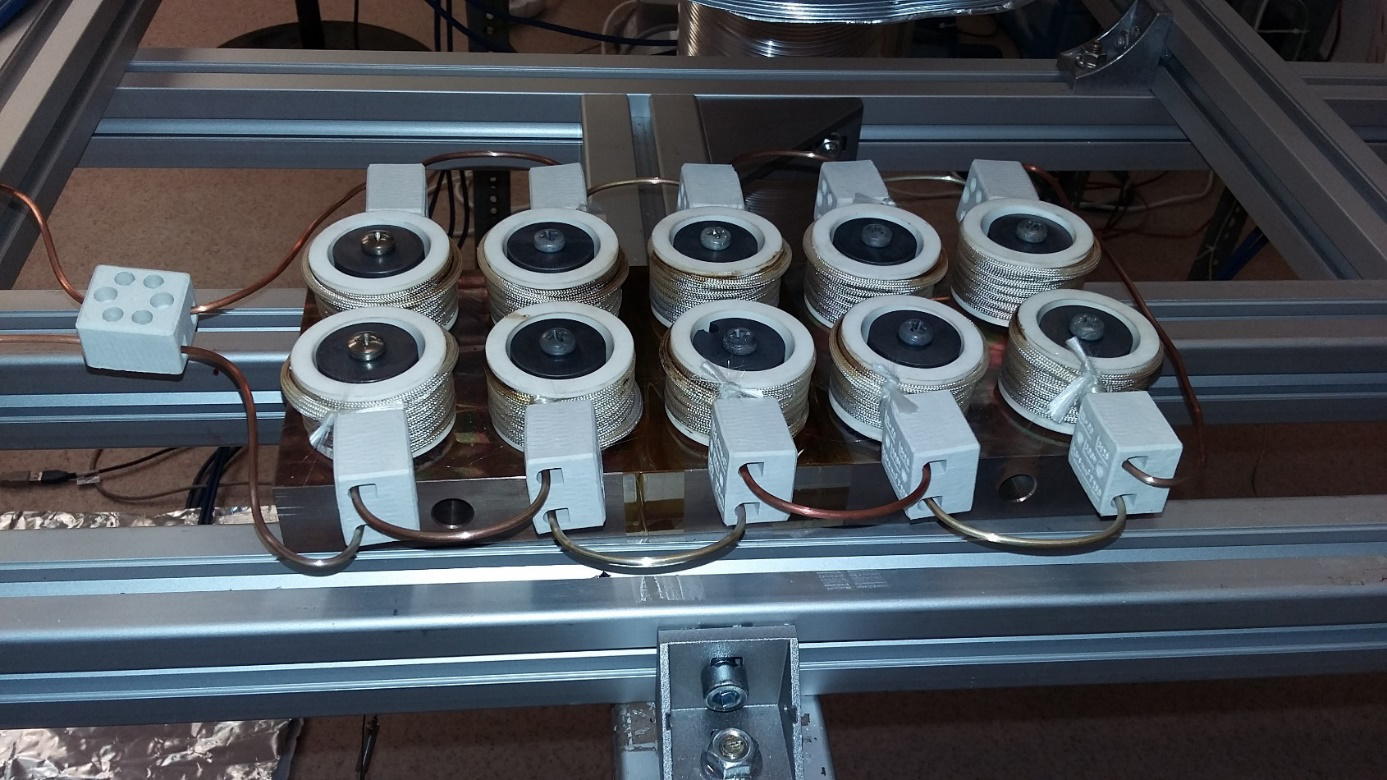

Full size cable loom assembly trials and tool development

.jpg)

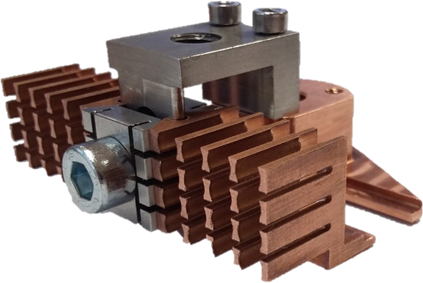

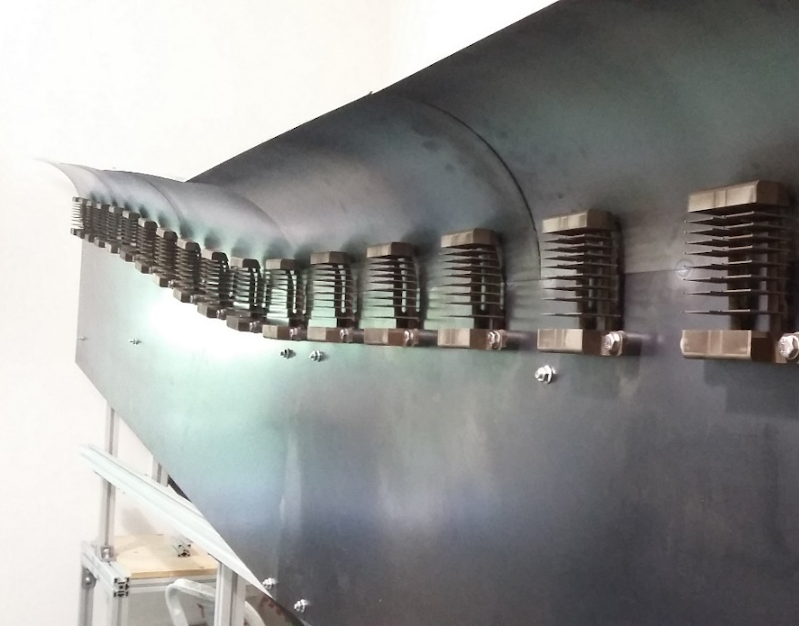

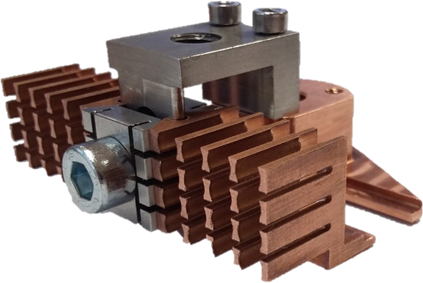

Divertor/In-vessel loom clamp

The in-vessel components of the ITER Diagnostics are located all over the inner shell of the Vacuum Vessel, in the Ports and on the Divertor Cassettes. The electrical transmission lines that transmit the signals from the sensors across the vacuum boundaries are Mineral Insulated Cables. These cables will be arranged into looms, which will be fixed to the vacuum vessel with different kinds of attachments.

The ITER tokamak is at a stage, where manufacturing and testing of each component are becoming more and more important. For this reason, to allow the ITER IO to assess feasibility, gain experience and obtain feedback with respect to the suitability of the current designs regarding handling and installation of in-vessel signal cables and loom components, GEMS Engineering has carried out a series of installation trials on full-scale mockups of in-vessel and divertor looms, upper and lower port marshalling area looms. Besides of installation trials, the scope of the work also covered the manufacturing and testing of in-port connectors, cable clamps and clips for in-vessel and divertor looms and marshalling areas.

Recent developments and results had also been summarized and presented at the 2022 Symposium on Fusion Technology event (https://soft2022.eu/).

See here our presented poster.

Infrastructure development for ITER’s in-vessel diagnostic signal transmission

Divertor/In-vessel loom clamp

GEMS Engineering have concluded a number of contracts with ITER IO with the aim to contribute to the development of the in-vessel electrical infrastructure that is responsible for signal transmission of numerous plasma diagnostic systems. Items to develop include cable trays, cable looms, clamps, clips, connectors, etc. Activities delivered to ITER include design, finite element analysis, prototype and mock-up manufacturing and testing development of special tooling, etc.

Examples of some manufactured prototypes and mockups are below. GEMS engineers and manufacturing experts have gained, among others, plenty of valuable expertise during the manufacturing of these items in terms of manufacturing optimization (speed, optimum raw material usage, cost, and alike).

We have also tested these components for functionality, installability, assemblability, etc.

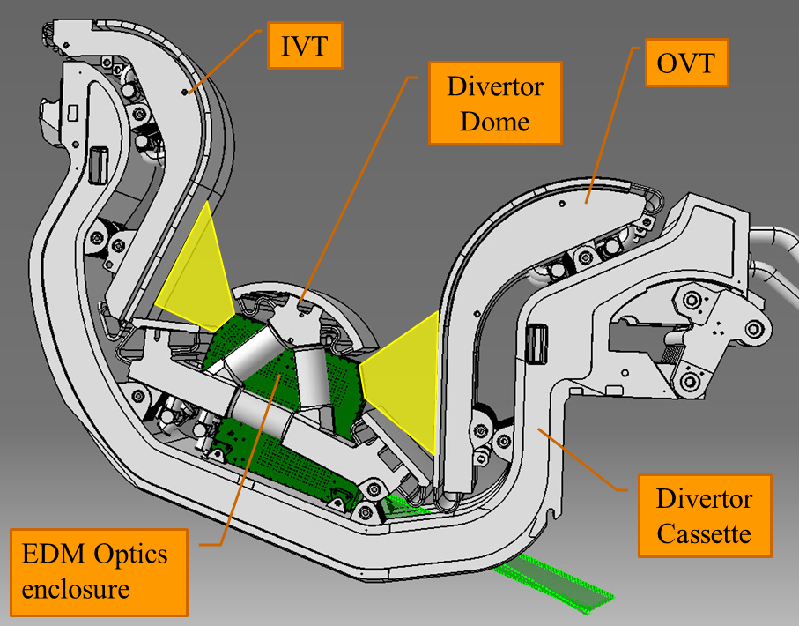

Erosion Deposition Monitor (EDM)

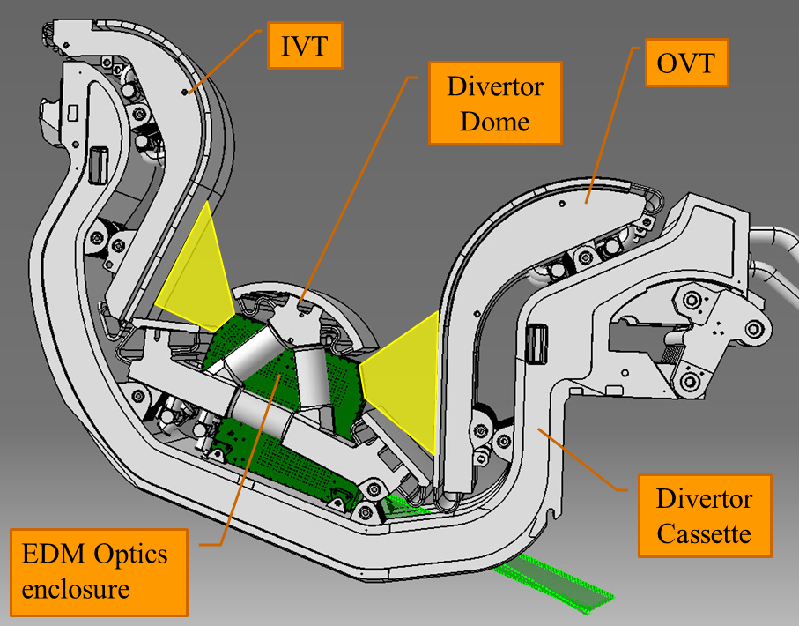

Front end optics enclosure with Vertical Targets (IVT left, OVT right)

GEMS, as the leader of the consortium composed of itself,

C3D,

Optimal Optik and AEMI has recently signed a Framework Contract with ITER IO. This 4+2 years Framework Contract targets the delivery of the mechanical design, analysis and prototyping of all components of the Erosion Deposition Monitor: the work affects the full system, from the in-vessel optics enclosure, which will be installed under the ITER Divertor dome, to the back end data collection system installed in the diagnostic hall. The goal of the Framework Contract is to progress the Erosion Deposition Monitor (EDM) design from its current state (post Conceptual Design Review, CDR);

- to the Preliminary Design Review, PDR, of the full system

- to the Final Design Review FDR, of the in-vessel and Port Cell (ISS and PCSS) components,

- deliver a set of prototype in-vessel components

- and deliver final manufactured in-vessel components ready for installation on ITER.

ITER Hard X-Ray Monitor (HXRM) Development

Our colleagues in the last 5 years have been working on the final design of the mechanical parts of the Hard X Ray Monitor which is a first plasma diagnostic system of the ITER machine, that will have a primary role in the detection and measurement of runaway electron events during the Hydrogen/Helium phase of the machine. The measurements will be analysed and used to improve the quality of subsequent plasma discharges to avoid/suppress the runaway electrons. The measurements will also be sent to the Plasma Control System and will be used to trigger the Disruption Mitigation Systems to prevent and/or stop runaway electron events.

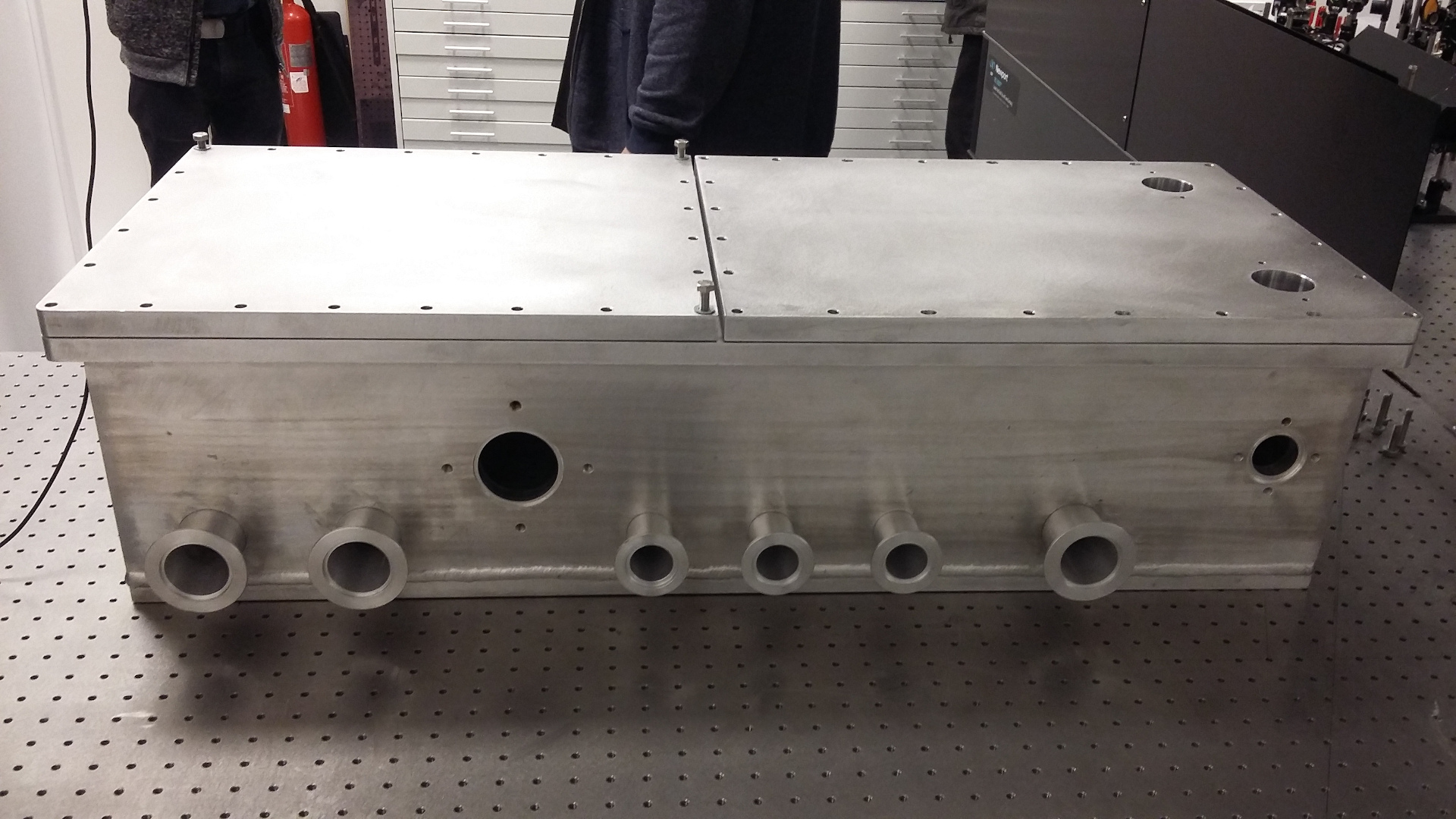

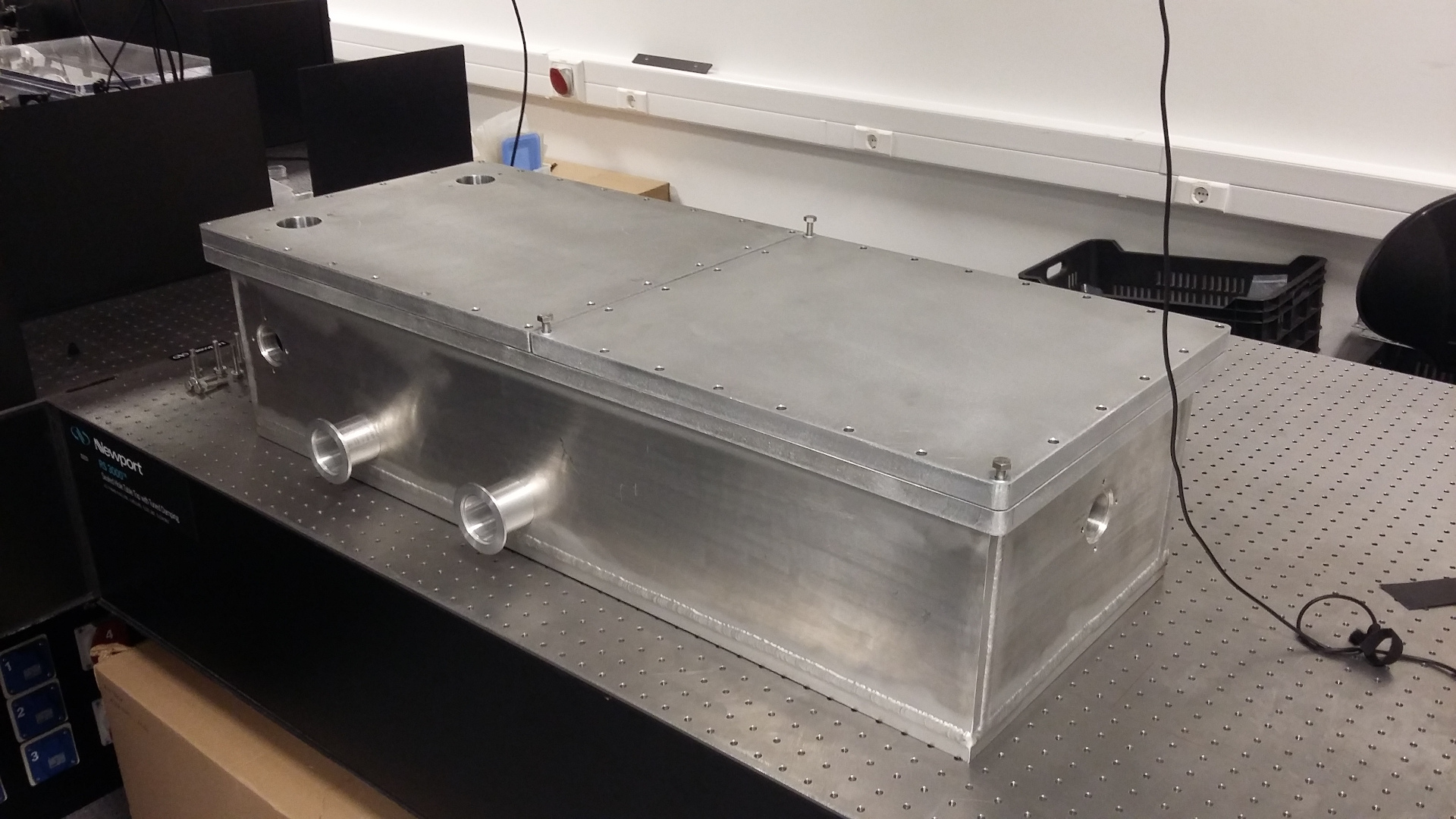

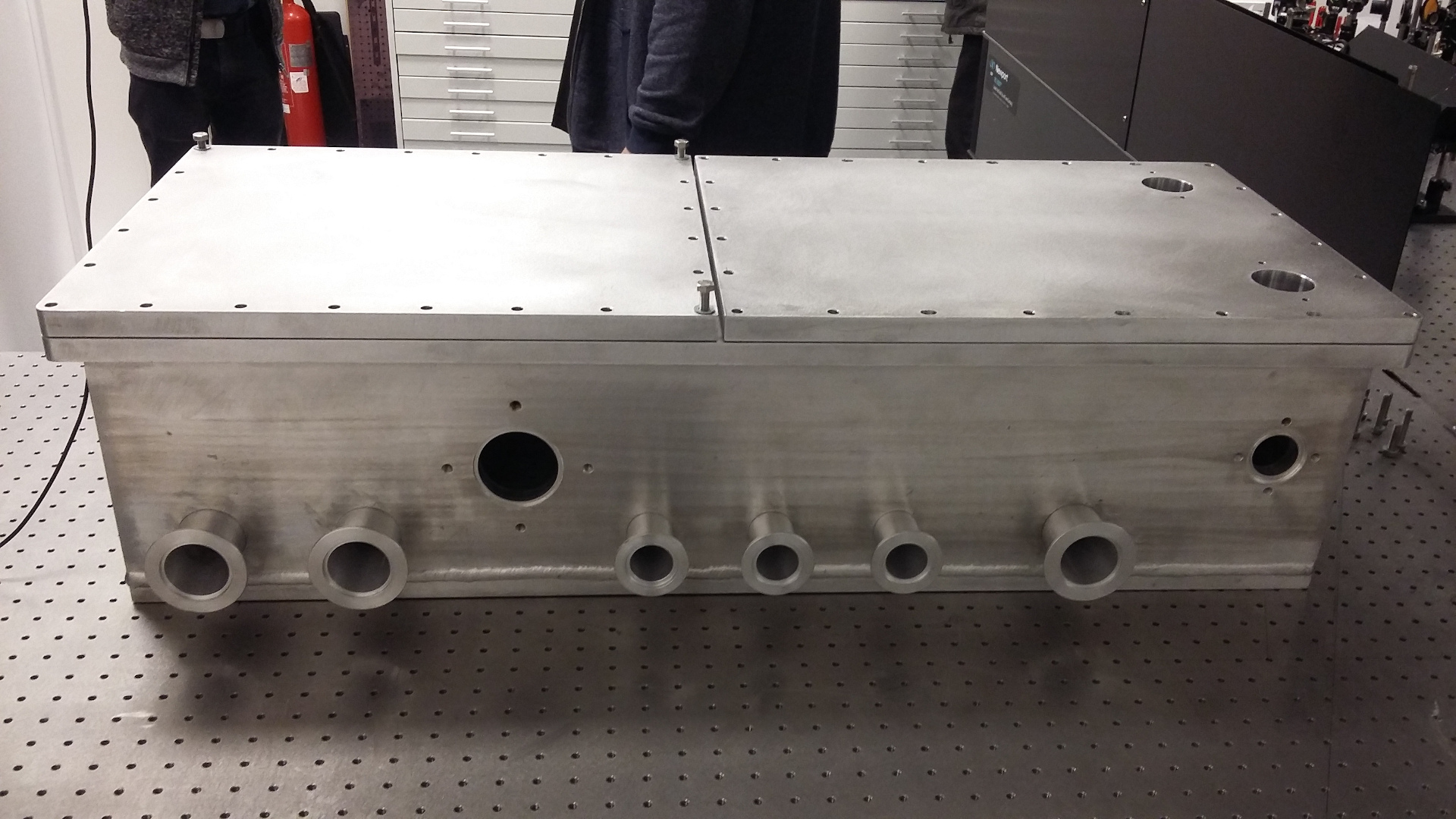

High-vacuum chamber for laser research applications

High-vacuum chamber for laser research applications

Upon the request and order of the University of Pecs, High-field Terahertz Research Laboratory, GEMS had designed and supplied a high-vacuum chamber to accomodate a target and various optical components to guide the beam of a terahertz laser.

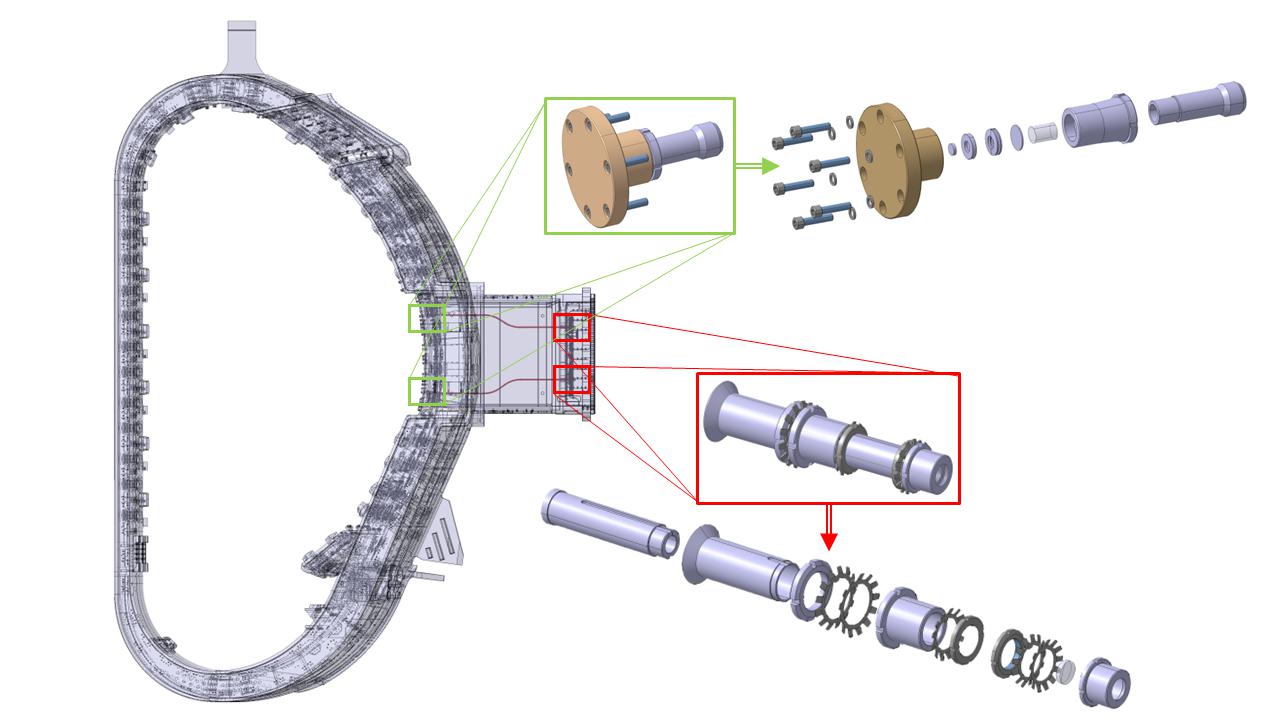

Manufacturing and delivery of in-sleeve supports for 55.C4 + 55.G8 diagnostic subsytems

In-sleeve support for 55.C4 + 55.G8 diagnostic subsytems.

We have manufactured - according to strictest ITER requirements - two in-sleeve supports for 55.C4 + 55.G8 diagnostic subsytems. This included the construction of two stainless steel in-sleeve support structures for 55.C4 +55.G8 transmission lines. The transmission lines cross the Tokamak building external walls at B1 level. The support and the transmission lines are installed by inserting the support through the rectangular sleeve pre-installed in the open and back filled.

The transmission lines comprise four rectangular stainless steel pipes with 200x100mm section, running from tokamak to diagnostic building.

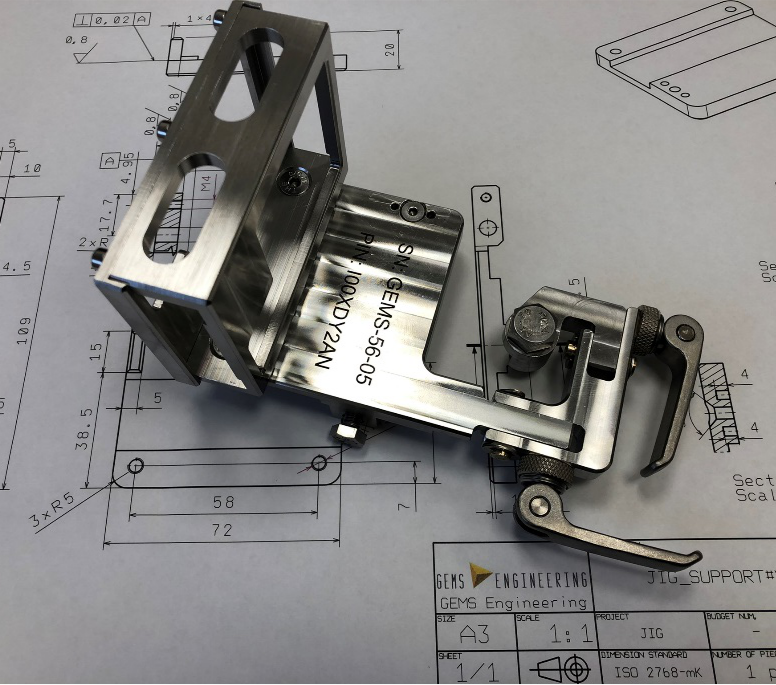

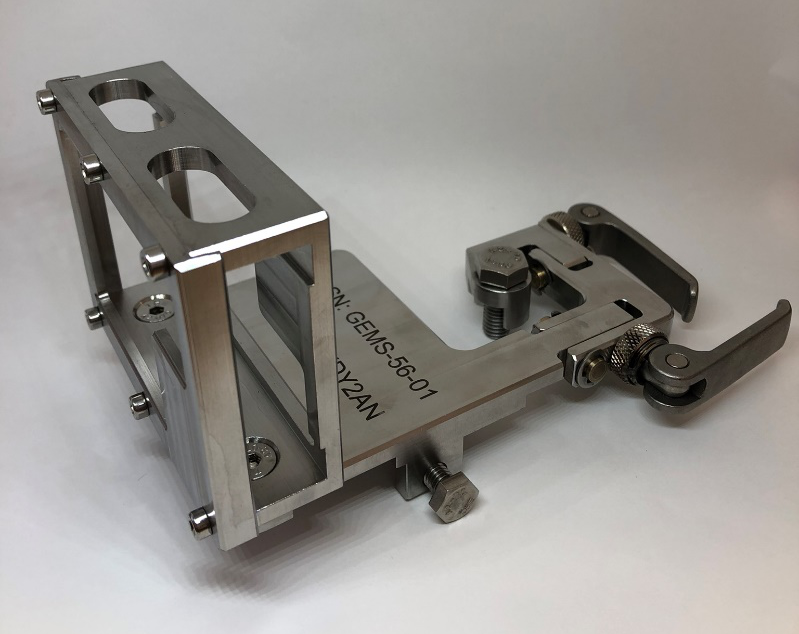

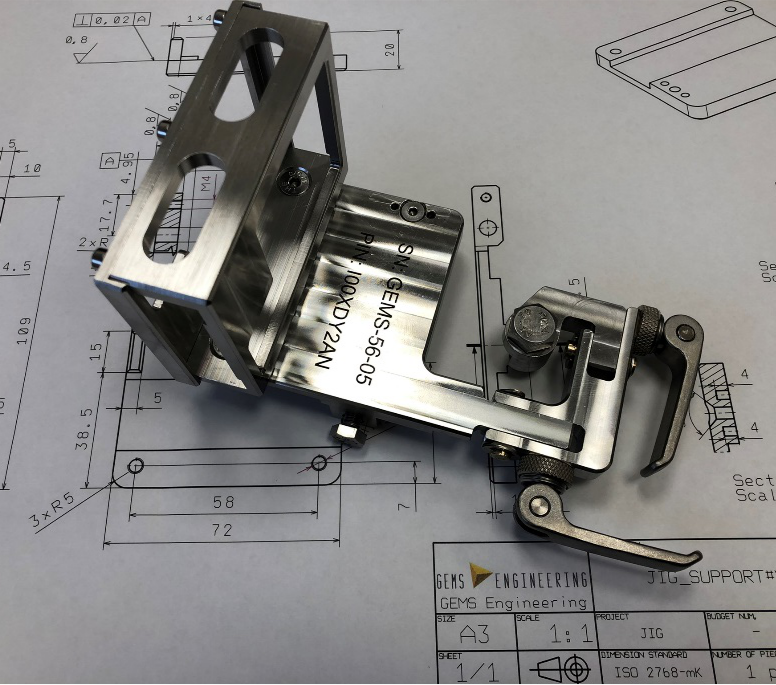

Alignment jigs for mounting the outer vessel steady state sensors of the ITER fusion reactor

GEMS Engineering Ltd. has become the first ever Hungarian private company, that has supplied components to be used for the assembly of the ITER fusion reactor.

The ITER machine will be used for scientific-technological purposes, to help the engineers and scientists know how the fusion plasma behaves at large scales. For this reason, one of the most important components of this huge machine are the small magnetic diagnostic sensors which will need to be perfectly mounted to have accurate signals from them before, during, and after the plasma pulses. GEMS Engineering Ltd. won the contract for the design and manufacturing of jigs for the alignment of the tangential and normal outer vessel steady state magnetic sensors in three sectors (2, 5 and 8). GEMS produced 10 pieces of jigs which would be used to accurately set-up all the 60 sensors. These jigs will “only” be used for aligning the sensors and they will be removed thereafter, in order not to contaminate the components that remain attached to the vacuum vessel. During the manufacturing, exclusively certified stainless steel and bronze raw materials were allowed to be used.

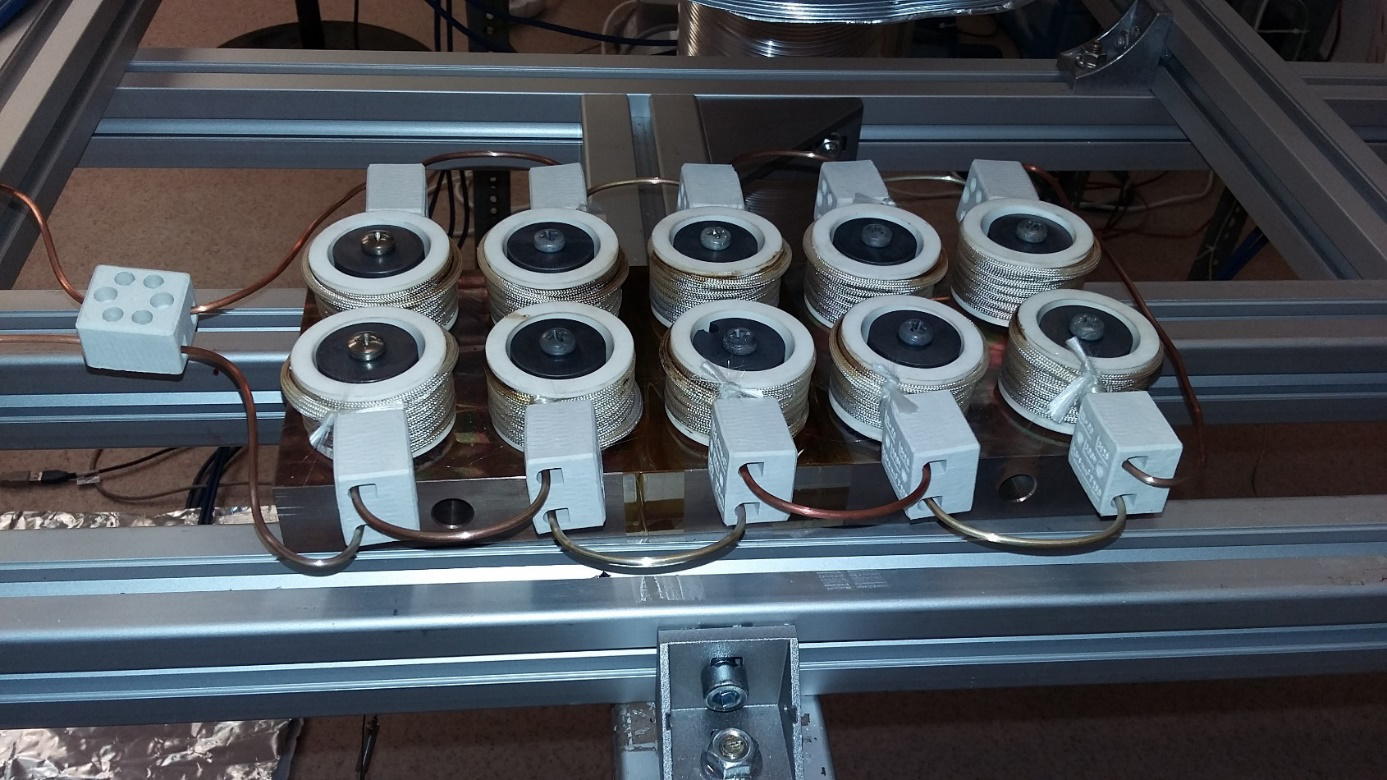

Tests of locking mechanisms for ITER

Induction heating of the bolt samples. A total of 15000 thermal cycles were performed between 100 and 200 °C

Different kinds of fasteners are used in ITER for the fixation of functional and structural in-vessel diagnostic components. The fasteners should retain initial tightening preload in vacuum under neutronic irradiation, thermal cycling and vibrations. These conditions can lead to incidental unscrewing of some bolts and nuts if they are not locked properly. They shall be equipped with some locking features which in most cases shall be remote handling compatible. One of the candidates on a role of a locking mechanism is Spiralock type thread. Custom designed so called First Wall Samples (CuCrZr) with M16 fine thread and standard M8 bolts (316L) were the subject of our studies. ITER-like thermal cycling alternating with vibration tests were applied to the components. Fasteners' loosening was monitored via periodic torque audits. For comparison with the Spiralock thread, tests with normal metric threads were also performed under the same experimental conditions.

.jpg)