The ITER device, currently under construction in the south of France, will study the potential of controlled nuclear fusion to provide energy for mankind. In order to study the behaviour of this device, a set of monitoring systems (referred to as Diagnostics) is required. These Diagnostics will provide the information required to understand the performance of the device.

GEMS Engineering is deeply involved in and fully devoted to the success of the ITER project. As a result, our main projects are in connection with ITER, and - more closely - to its diagnostic systems.

Infrastructure development for ITER’s in-vessel diagnostic signal transmission

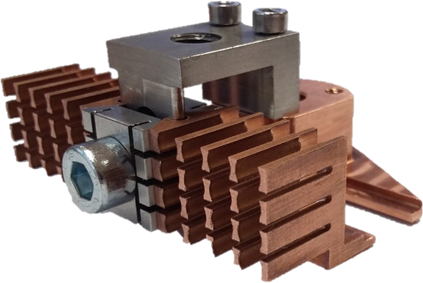

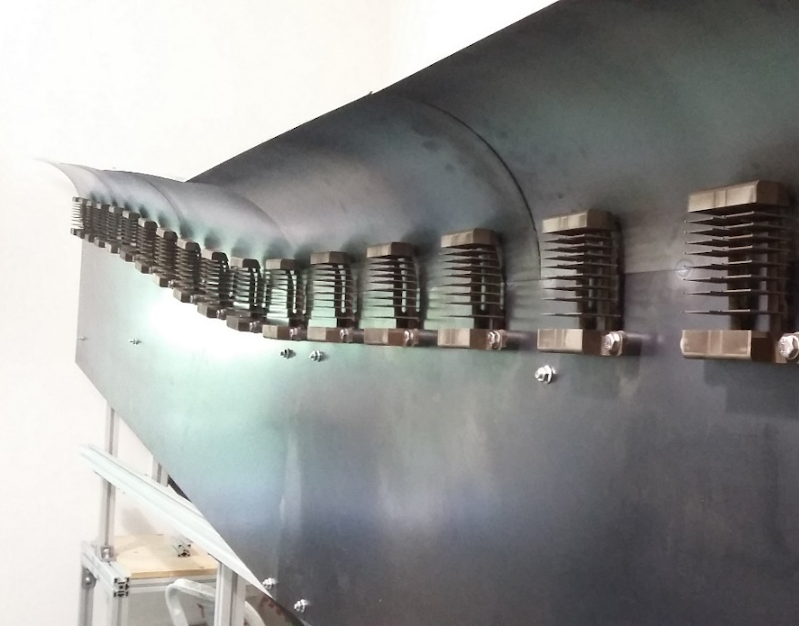

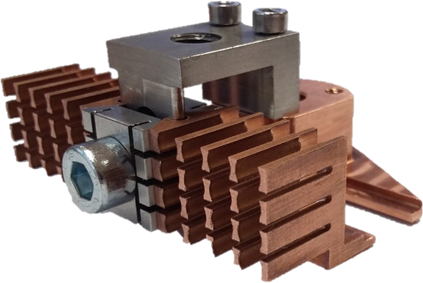

Divertor/In-vessel loom clamp

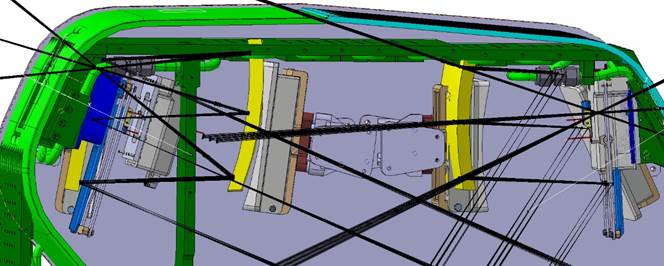

GEMS Engineering have concluded a number of contracts with ITER IO with the aim to contribute to the development of the in-vessel electrical infrastructure that is responsible for signal transmission of numerous plasma diagnostic systems. Items to develop include cable trays, cable looms, clamps, clips, connectors, etc. Activities delivered to ITER include design, finite element analysis, prototype and mock-up manufacturing and testing development of special tooling, etc.

Examples of some manufactured prototypes and mockups are below. GEMS engineers and manufacturing experts have gained, among others, plenty of valuable expertise during the manufacturing of these items in terms of manufacturing optimization (speed, optimum raw material usage, cost, and alike).

We have also tested these components for functionality, installability, assemblability, etc.

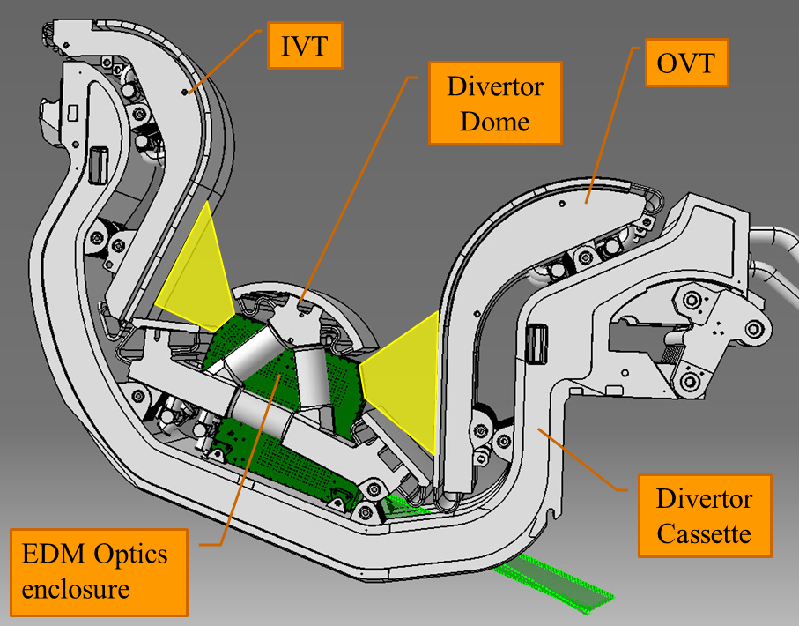

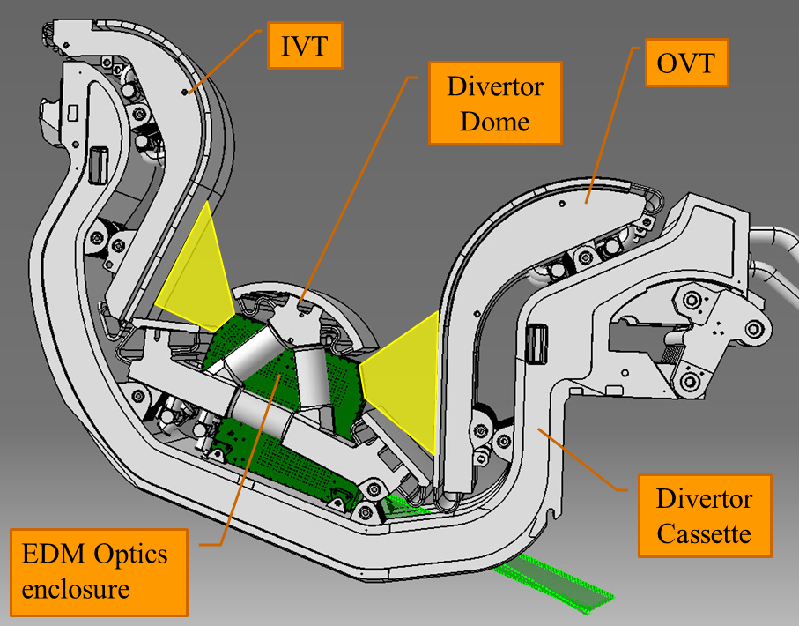

Erosion Deposition Monitor (EDM)

Front end optics enclosure with Vertical Targets (IVT left, OVT right)

GEMS, as the leader of the consortium composed of itself,

C3D,

Optimal Optik and AEMI has recently signed a Framework Contract with ITER IO. This 4+2 years Framework Contract targets the delivery of the mechanical design, analysis and prototyping of all components of the Erosion Deposition Monitor: the work affects the full system, from the in-vessel optics enclosure, which will be installed under the ITER Divertor dome, to the back end data collection system installed in the diagnostic hall. The goal of the Framework Contract is to progress the Erosion Deposition Monitor (EDM) design from its current state (post Conceptual Design Review, CDR);

- to the Preliminary Design Review, PDR, of the full system

- to the Final Design Review FDR, of the in-vessel and Port Cell (ISS and PCSS) components,

- deliver a set of prototype in-vessel components

- and deliver final manufactured in-vessel components ready for installation on ITER.